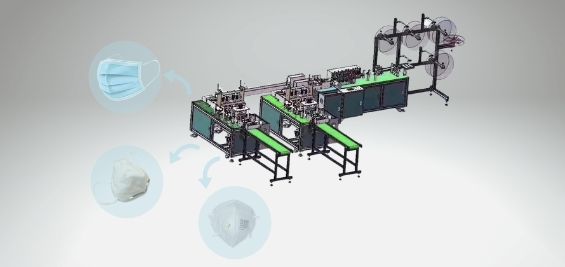

Since the outbreak of the COVID-19, the global mask resources are very scarce, and “unable to buy masks” has become a hot topic in the society. At present, Xingshi Machinery production Workshop, located in Panyu District, Guangzhou, China, adopts Mitsubishi automatic mask machine production line, producing 1000 masks per minute.

The appearance and structure of the mask:

The disposable mask is composed of a non-woven protective layer, a nose line and an ear hanger, and the main non-woven protective layer is from the inside to the outside, namely, a water absorption layer, a filter layer and a waterproof layer.

At present, there are mainly two types of equipment for producing medical masks: fully automatic mask production line and semi-automatic mask production machine. Semi-automatic mask machine each equipment only completes one of these processes.

The technological process of automatic mask machine:

First, carry out three-layer pressing of the non-woven fabric, followed by the whole side, sewing the nose clip and the whole side, “sewing” the nose feeding line, “pushing the nose line” and other processes, then folding the three-layer non-woven fabric, then flattening the folded plane, cutting it, and then carrying out the second cutting to ensure that the edge of the mask is neatly trimmed and then the ear rope is fixed by hot pressing. Finally, the whole knife is cut. Finally, the products are tested, and the tested products are sterilized and disinfected to complete the final packaging of the finished products.

Therefore, the requirements of the mask machine are high speed to maximize production capacity, and high precision requirements, such as edge wrapping, cutting, fixing and other processes must be accurate. The finished product must meet the requirements of high quality.

It is necessary to meet both high speed and high precision, which has high requirements for the control part, drive part and mechanical function of the production line.

According to these requirements, Mitsubishi offers a variety of solutions. For example, for the configuration scheme of medium and large mask machine, we can choose the high-performance R series PLC configuration, while for the economical mask machine scheme, we can use the economical configuration scheme of FX series PLC+ FX5-80SSC-S simple control module.

Configuration scheme of medium and large mask machine:

First of all, the R series (RJ618T11; RX40C7, RD62P2, RD77MS16 (2), RDBCPU, R51P) PLC is the main control.

The servo of J4-B is equipped with RD77MS16 to realize the processing of 13 stations and the synchronous control of various complex processes. The GOT2000, is used in the man-machine interface to easily realize data monitoring. The remote RO input module completes the input and acquisition of image sensor, origin signal and limit signal. This set of system features: the selection of high-performance Mitsubishi PLC, program processing time will be shorter, can effectively shorten the production beat; then Mitsubishi high-speed, high-precision J4 servo, to ensure the processing accuracy of equipment production, improve the quality and efficiency of mask production. In addition, the anti-interference requirement of the automatic production line is also relatively high, we use optical fiber network servo, which can effectively prevent external interference and ensure the stability of equipment operation.

Configuration scheme of economical mask machine:

The economical mask machine scheme is FX5U-80MT series PLC, with a FX5-80SSC-S simple motion module, 6 stepper motors and 8 JE-B servo motors. In addition, some modules or fixed modules can be selected to expand according to the needs of the system. Features: the system configuration is simple, the structure is also very compact, can save costs. The FX5-80SSC-S simple motion module can carry up to 8 shafts, which can meet the operation needs of small equipment. The servo system can set the parameters of our positioning module through Mitsubishi GX works3 programming software to achieve a variety of control modes. To improve the production quality of masks.

The above is the Mitsubishi mask machine solution, with a high performance-to-price ratio, but also has the advantage of one-stop solution, is the current stage of the more ideal system solution. Customers can also make appropriate adjustments according to their specific needs.

Other benefits are as follows:

1. Convenient and fast programming: convenient and fast programming in practical application scenarios can greatly improve the efficiency of development. GX WORKS3 programming software integrates a large number of functional blocks, which only need to drag the corresponding functional blocks to the program when programming, which is very intuitive and convenient. Servo configuration can also be directly specified in the GX WORKS3 special configuration interface servo type, selection and setting.

2. Rapid realization of multi-axis synchronization: in order to achieve the ability of high-speed and high-precision production, the mask machine needs to achieve precise cutting, multi-component adhesive cutting, pressing and other actions in the process, if synchronous control is not used, then every step must be stopped for operation, which will greatly reduce our production beat. Therefore, in the practical application, we must use the advanced synchronization function of the motion module, and the reason why we choose the RD77MS16 and FX5-80SSC-S simple control module in the scheme. These two modules can not only carry out common positioning control of our servo, but also support the advanced synchronous control function of multiple servos. However, RD77MS16 is faster than FX5-80SSC-S and can control more axes.

3. Cam function: the cam data for rotary cutting can be generated automatically by setting the specified software, and the cam data can be generated simply by inputting feed length, synchronous width, cam resolution and so on.

4. Synchronous deviation adjustment: for example, for the cutting of masks, the spacing must be consistent. In theory, high precision can be achieved through synchronous control, but in practice, it is very difficult to achieve, because of the accuracy of the machine and the characteristics of the material. environmental changes and these factors will lead to a decline inaccuracy. Therefore, in the actual scheme, it is necessary to use the color code compensation function to realize the on-line position adjustment in the synchronous operation. The color code sensor is used to detect the current position and adjust the position online in real-time. For example, in the production of the mask, the edge of the cut material is detected by the sensor, and then the installation position of the suction valve is adjusted in real-time according to its position, so as to eliminate the deviation

Application of Mitsubishi servo in mask machine

1)One drag two plane mask machine configuration, speed 110pc / min, servo adopts PLC body pulse control.

| Name | Part No. | QTY | Description |

| Servo driver | MR-JE-200A | 1 | 1.5kw servo driver |

| Servo motor | HG-SN152J-S100 | 1 | 1.5kw servo motor |

| Power cable | MR-PWCNS4-5M | 1 | 5m power cable |

| Encoder cable | MR-J3ENCBL5M-L | 1 | 5m encoder cable |

| Servo driver | MR-JE-70A | 3 | 750w servo driver |

| Servo motor | HG-KN73J-S100 | 3 | 750w servo motor |

| Power cable | MR-PWS1CBL5M-A2-L | 3 | 5m power cable |

| Encoder cable | MR-JENCBL5M-L | 2 | 5m encoder cable |

| PLC | FX3U-64MT/ES-A | 3 | 64 points |

2) The N95 mask machine is configured with a speed of 80 pieces per minute. There are 13 drive shafts, of which 7 servo axes are based on Mitsubishi SSCNET bus. Step-by-step main machine plus 2-axis pulse positioning module control.

| Name | Part No. | QTY | Description |

| Servo driver | MR-JE-40B | 2 | 400w servo driver |

| Servo motor | HG-KN43J-S100 | 2 | 400w servo motor |

| Servo driver | MR-JE-70B | 4 | 700w servo driver |

| Servo motor | HG-KN73J-S100 | 4 | 700w servo motor |

| Servo driver | MR-JE-200B | 1 | 2kw servo driver |

| Servo motor | HG-SN202J-S100 | 1 | 2kw servo motor |

| PLC | FX5U-80MT+32inputs +16outputs | 1 | 128 points |

| Motion controller | FX5U-80SSC-S + FX5-16TYT/ES-H | 1 | 8-axis synchronization + 6-axis pulse |

Mask machine installation site

Our company’s mask machine scheme is also being shipped one after another, from installation to commissioning we have professional engineering and technical support, if you have any questions, welcome to consult: sales@kwoco-plc.com.